Below is just a few equipment layouts.

See something you'd like but want to alter it a little bit?

Give us a call! We'll be glad to design your own equipment layout.

Give us a call! We'll be glad to design your own equipment layout.

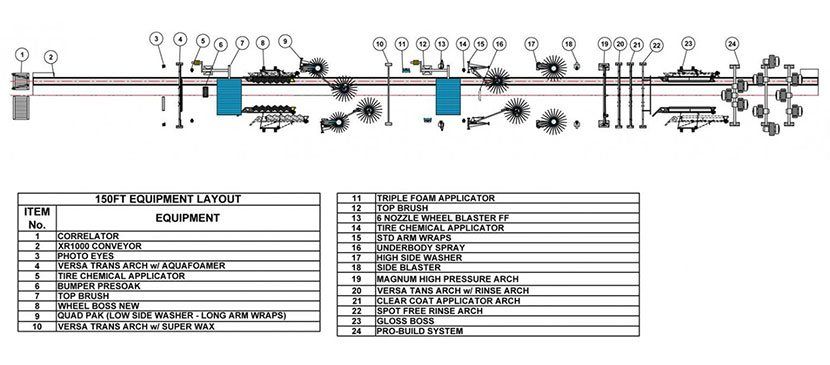

150 Ft Tunnel Equipment Layout

150 Ft Tunnel Equipment Layout